Description

Overview

Dansensor® LeakPointer® 3 and Dansensor® LeakPointer® 3+ leave no leaks unnoticed. They are highly accurate and able to carry out non-destructive leak detections of leak sizes down to 50 µm. This makes them indispensable in MAP-lines where undetected leaks can be costly and cause damage to the customer relationships. The Dansensor LeakPointer 3 and Dansensor LeakPointer 3+ are both approved to carry out leak detections in the food industry.

The Dansensor LeakPointer 3 and Dansensor LeakPointer 3+ creep testing machines carry out leak detection of small size leaks, thereby ensuring a consistently high product quality.

Leak detectors:

Besides the Dansensor LeakPointer 3 and Dansensor LeakPointer 3+ we offer additional products for leak detection in Modified Atmosphere Packaging. These are described below.

- Dansensor® LeakPointer® H2O

Dansensor LeakPointer H2O is a premium water bath for visual leak testing (bubble test) on almost all types of packaging. The leak detector is used for quality control checks, R&D package testing and process optimization on the packaging line. - Dansensor® LeakMatic ll

Dansensor LeakMatic ll is preferred by many operators because of its ability to test 4-6 packages per minute, which can be attributed to the non-destructive seal testing method it applies. Besides, this leak detection equipment is recognized for reducing the amount of waste in MAP processes. - Dansensor® Lippke® 5000

Dansensor Lippke 5000 provides reliable seal strength and pressure leak testing of many types of packaging. It can be used production, laboratory environments and throughout the supply chain to test package integrity. - Dansensor® Lippke® VC1400

Dansensor Lippke VC1400 provides reliable seal strength and pressure leak testing of many types of packaging. It can be used for quality control checks, R&D package testing and process optimization on the packaging line.

Features & Benefits

Features

- Non-destructive leak testing

- Ensures product quality

- Detects micro leaks down to 50 microns

- User interface harmonized with other Dansensor instruments

- Data collection and data sharing options

- Easy to operate

Additional benefits Dansensor LeakPointer 3:

- Immediate calculation of hole size

- Down to 10-second test cycle

- Additional option; Dansensor® PackBase

Additional benefits Dansensor LeakPointer 3+:

- Tests multiple large packages at once

Benefits

- Designed for the food industry

- Easy operation via touch screen

- Scan barcode or choose program to operate

- Option to prompt user for additional measurement input

- Read the leaks in microns

- Immediate vacuum holding lid down (with visual indicator)

- Integrated Delta-P meter

- Auto data logging

- Data export per cycle via LAN

- Printing facility (USB)

- Low sensitivity to surrounding CO2 levels

Technical Specifications

| Available configurations | Dansensor LeakPointer 3 | Dansensor LeakPointer 3+ |

| Package types | Flexible and rigid packages. Individual packages | Flexible and rigid packages. Multiple packages |

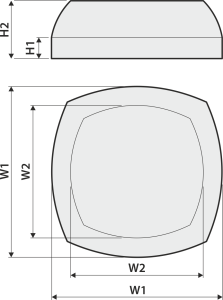

| Maximum product size (mm) – See illustration | With Dansensor PackFix: W1= 325, W2 = 295 H1= 40, H2 = 86 Without Dansensor PackFix: W1= 325, W2 = 268 H1= 40, H2 = 110 |

W1 = 465, W2 = 363 H1= 40, H2 = 155 |

| Power supply | 100-264 VAC, 50/60 Hz | 115 VAC, 60 Hz / 230 VAC, 50 Hz |

| Dimensions (mm) & weight | Lid open: 543 x 400 x 617 (HxWxD) 20 kg |

Lid open: 751 x 555 x 812 (HxWxD) 50 kg |

| Air supply | 5.5 ± 0.5 bar (venturi vacuum system) | Vacuum pump integrated |

| Chamber vacuum | Down to 750 mbar delta pressure | Down to 800 mbar delta pressure |

Applications

Non-destructive leak testing of MAP packages

Detection of leaks in MAP packages down to 50 microns

For a variety of food, beverage, pharmaceutical and medical packages using MAP.

Some examples of our customer applications include:

- Snack Foods

- Bakery

- Coffee

- Ready-to-eat

- Pizza

- Meats

- Cheese

- Fish

- Fruit, salads & Vegetables

- Pet Foods

- Pharmaceutical Packaging/Medical Devices

- Catering service