What is the difference between the Dansensor CheckPoint 4 and CheckMate 4 gas analyzers?

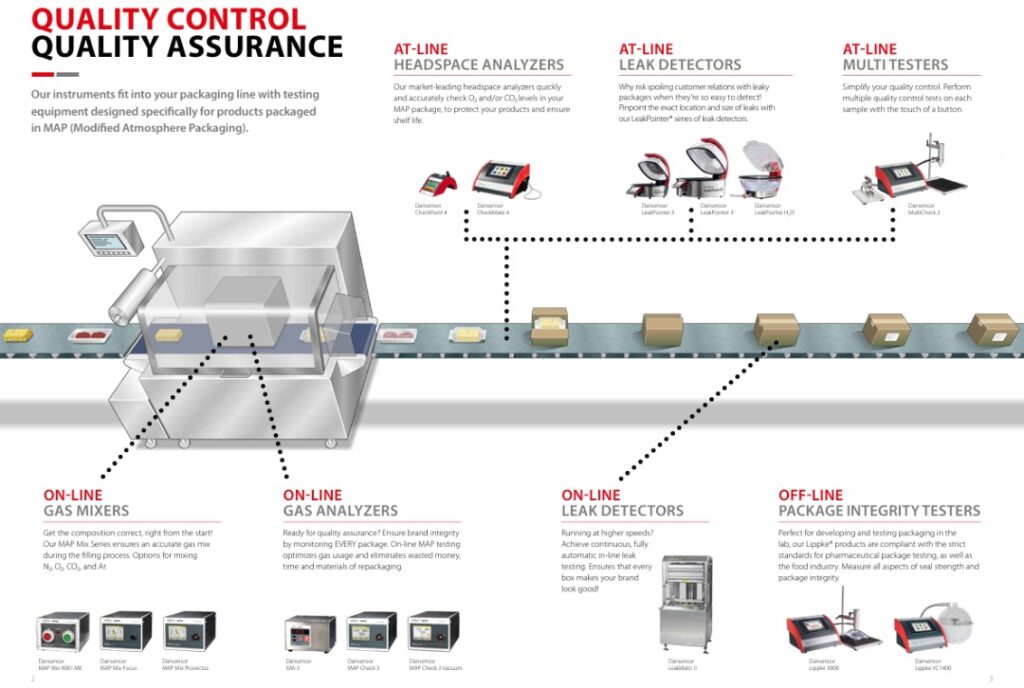

The Dansensor CheckPoint 4 and CheckMate 4 are high-precision gas analyzers that help you control quality in Modified Atmosphere Packaging (MAP) applications. Both analyze residual gases (typically O₂ and/or CO₂) in food, medical, and pharmaceutical packages, but they differ in design, use case, mobility, throughput, and flexibility.

This detailed comparison will help you choose the analyzer best suited for your production environment:

Dansensor CheckPoint 4 – Handheld, Battery-Powered Gas Analyzer

Key Features:

- Portable and cordless: Ideal for mobile spot-checks across production lines

- Lightweight and ergonomic: Weighs approx. 600g — can be used one-handed

- Fast measurement: Results typically in under 10 seconds

- Sensor options: Available in O₂-only or O₂/CO₂ dual sensor versions

- User-friendly touchscreen: 3.5″ color display with intuitive interface

- Data storage: Internal memory, Bluetooth®, and USB export

- User-replaceable sensor: Sensor module can be changed manually by the user, minimizing downtime

Typical Use Case:

✅ Quality inspectors perform random gas checks at multiple packaging lines during shift changes

✅ Ideal for low- to medium-throughput environments, where mobility and quick checks are required

Dansensor CheckMate 4 – Stationary, Bench-Top Gas Analyzer

Key Features:

- Fixed installation: Designed for central QA labs or at-line benches

- Higher throughput: Suitable for continuous, repetitive testing of sample batches

- Sensor technology: High-precision optical sensor for O₂ (optionally IR for CO₂)

- Barcoded sample tracking: Optional barcode scanner for product traceability

- Data management: Built-in printer, Ethernet, and USB connectivity

- User calibration: Calibration routines for regulatory compliance (e.g., BRC, ISO, FDA)

- Modular configuration: Can be combined with external automation such as carousel samplers

Typical Use Case:

✅ A QA team performs gas analysis on samples from every production batch in a controlled lab setting

✅ Recommended for high-volume operations or where data traceability is critical

Final Notes:

- If flexibility and mobility are key, the CheckPoint 4 offers unmatched convenience.

- If data traceability and high-throughput testing are your priority, the CheckMate 4 is the ideal solution.

Still unsure which analyzer best suits your packaging line? Our technical team at Calia Technology Sdn Bhd is ready to assess your process and recommend the most efficient solution tailored to your QA goals.

Click here for more details.