VP Pigging Cleaning System

Pipeline pigging system – Product recovery and cleaning

The Pigging System, also known as a Pipeline Cleaning or Product Recovery System, uses a slightly oversized, flexible projectile called a “pig” to clean and recover residual product inside pipelines. The pig is pushed through the pipeline using water, other liquids, compressed air or gas, or even the product itself, minimizing waste and maximizing product recovery.

Versatile pigging solutions

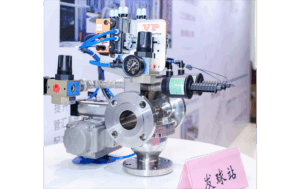

Pigging Systems are available in various types, such as Economic Pipeline Cleaning Systems, Sanitary Pipeline Cleaning Systems, and Sterile Pipeline Cleaning Systems. They can be fully customized to suit different industries and processing needs, with manual, semi-automatic, or fully automatic options. The system typically includes launch stations, receiving stations, and pigs, and can be supplied as a complete turnkey solution.

How the Pigging System Works

A pig launcher and receiver are installed at opposite ends of the pipeline, equipped with valves that manage the compressed gas or liquid used to propel the pig. Pigs can be easily inserted or removed with catchers for simple maintenance and operation.

Wide Range of Applications

Pipeline Pigging Systems are used across multiple industries, including petrochemical production, food processing for products such as sauces, condiments, chocolate, oyster sauce, and fermented pastes, beverage manufacturing, pharmaceutical liquids, dairy production, consumer goods such as cosmetics, toiletries, detergents, and laundry liquids, pet food production, paints and coatings, and new energy materials like lithium battery slurry.

Proven Technology and Innovation

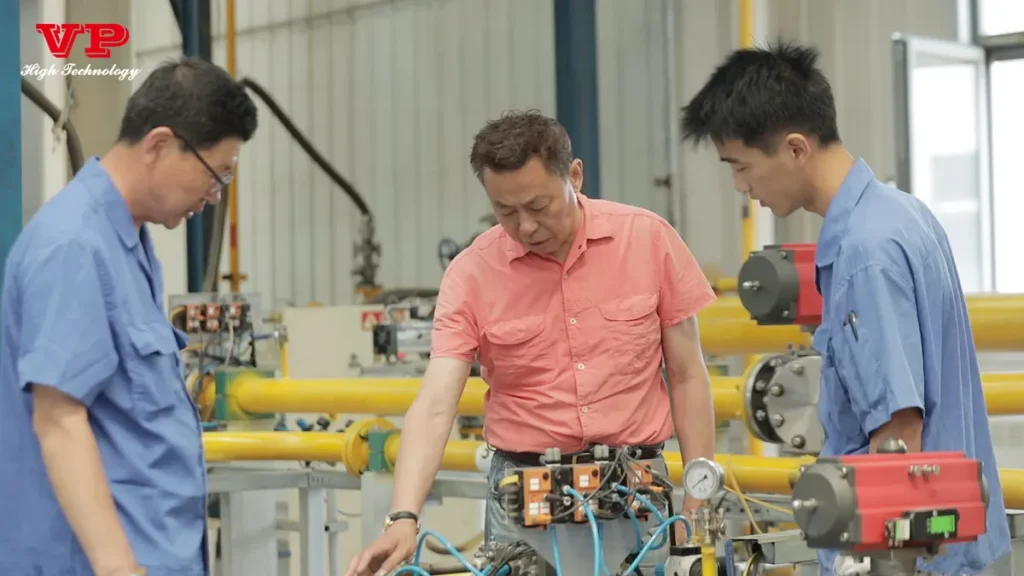

As a trusted manufacturer, BJVP showcases its Pigging Systems at leading industry exhibitions, demonstrating how this technology improves pipeline maintenance and production efficiency. The system simplifies operations by using a single-stage impeller and requires no extra sealing or lubrication equipment, resulting in lower maintenance and higher reliability.

Key Advantages

High-efficiency, self-cleaning pipelines reduce product waste and cross-contamination. Multiple products can share the same pipeline, saving space and cost. The system offers simple installation, minimal wear parts, and a user-friendly design with robust, reliable performance, ensuring long-term, trouble-free operation.

Get in Touch

To learn more about this Pigging System and how it can benefit your production process, please contact our team today. We’re ready to provide detailed information, technical support, and tailored solutions to fit your specific needs.