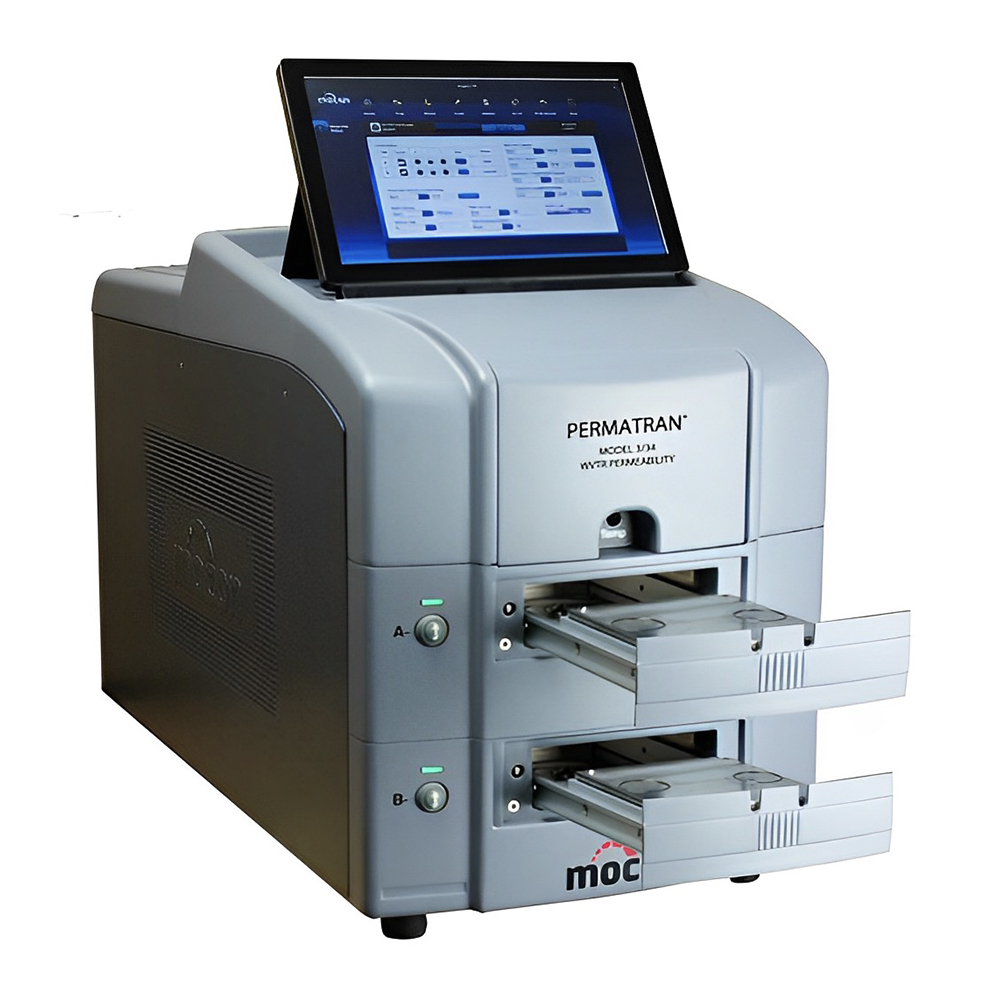

Advanced water vapor permeation analyzer for high-precision barrier film testing

The AMETEK MOCON PERMATRAN-W 3/34 is a high-performance water vapor transmission rate (WVTR) analyzer that delivers precise and repeatable permeation testing for medium-to-high barrier films. Across the food, pharmaceutical, electronics, and packaging industries, manufacturers rely on this system where moisture control directly affects product integrity and shelf life.

Using advanced sensor technology together with automated humidity control, the PERMATRAN-W 3/34 delivers reliable moisture barrier analysis. As a result, manufacturers can optimize packaging materials, prevent product degradation, and meet industry regulations more efficiently.

Highly accurate WVTR testing for quality control

At the core of the system, next-generation infrared sensor technology enables ultra-sensitive detection of water vapor. Consequently, the PERMATRAN-W 3/34 performs exceptionally well when testing films with moderate to high moisture resistance. Compliance with ASTM F1249 and ISO 15106-2 standards further ensures alignment with global packaging and material testing requirements.

The system also allows operators to test multiple samples simultaneously, which significantly reduces testing time while improving laboratory throughput. Meanwhile, automated relative humidity (RH) and temperature control maintain stable, repeatable conditions and minimize variability to enhance data reliability.

User-friendly operation with automated features

Designed with usability in mind, the permeation analyzer features an intuitive touchscreen interface combined with automated data collection. Quality control teams and R&D laboratories can therefore monitor moisture permeability trends in real time with greater efficiency.

Beyond day-to-day operation, the system performs automated calibration and continuous self-diagnostics to reduce routine maintenance requirements. These features support long-term reliability while minimizing user intervention. Its compact, bench-top design also allows the analyzer to integrate seamlessly into a wide range of laboratory environments without occupying excessive space.

Key features of the AMETEK MOCON PERMATRAN-W 3/34

• High-precision WVTR testing – Advanced infrared sensor technology delivers ultra-sensitive moisture detection.

• Simultaneous multi-sample analysis – Dual film testing chambers increase efficiency and throughput.

• Standards compliance – The system meets ASTM F1249 and ISO 15106-2 industry regulations.

• Automated RH and temperature control – Built-in controls ensure consistent, repeatable testing conditions.

• User-friendly interface – Touchscreen controls and automated data logging streamline operation.

• Compact, laboratory-ready design – The analyzer supports high-precision material testing in both R&D and production settings.

Enhance packaging performance with reliable WVTR analysis

Ultimately, the PERMATRAN-W 3/34 serves as an essential solution for manufacturers and researchers who aim to improve moisture barrier performance in packaging materials. By delivering accurate and dependable WVTR analysis, the system helps extend product shelf life, enhance packaging quality, and support regulatory compliance.

Click here to know more.