Lundberg Tech - Complete Waste Handling Solutions

Lundberg Tech delivers customised systems that capture, cut, convey, collect, compact, and clean production waste directly at the source. With over 40 years of expertise, their solutions help manufacturers boost productivity, reduce downtime, and support sustainable operations.

Your Process

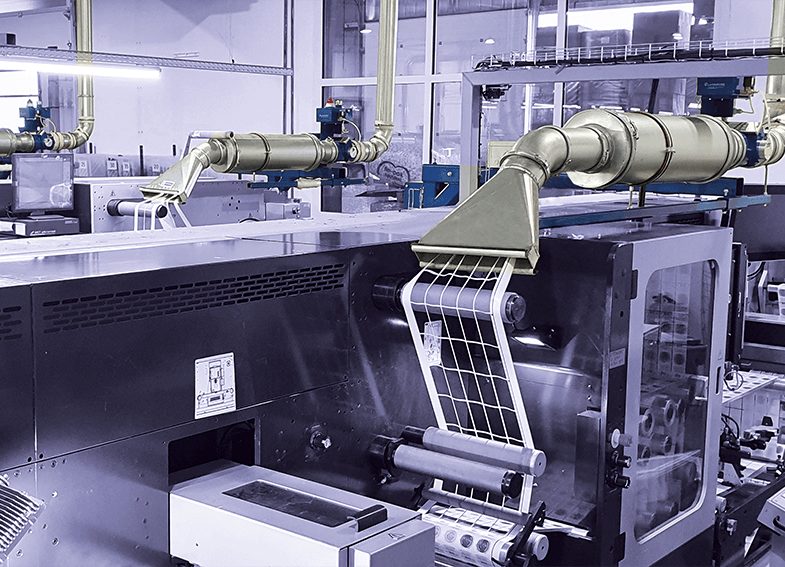

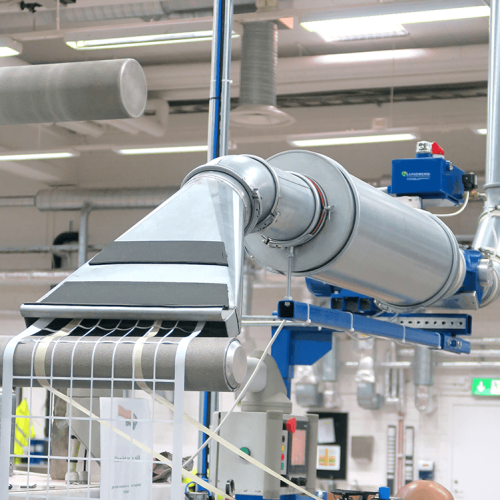

Capture - Waste Removal at the Source

Lundberg Tech systems capture waste directly from production or packaging lines, preventing dust and debris from spreading. This ensures cleaner work environments and consistent product quality.

Cut - Effecient Size Reduction

Captured waste is fed into precision cutters or granulators, reducing it into small, manageable pieces. This makes handling, transport, and recycling more efficient.

Convey - Seamless Waste Transport

Once cut, waste is pneumatically conveyed through a closed pipeline system to a central collection point. This eliminates manual handling and keeps production areas clear.

Collect - Centralised Waste Management

All waste is gathered in sealed containers, bins, or compactors, ready for recycling or disposal. This step improves workplace safety and reduces contamination risks.

Compact - Space-Saving Storage

Optional compacting units reduce the volume of waste, lowering transport costs and storage requirements.

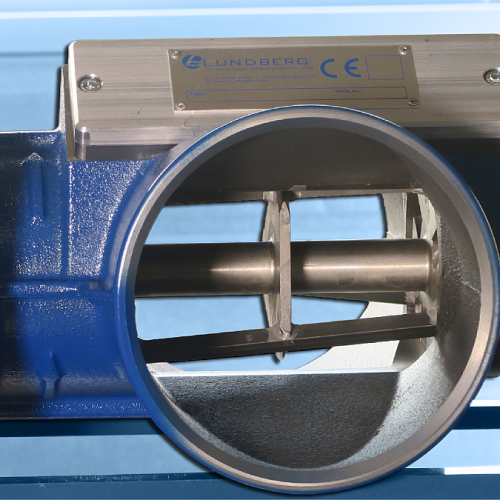

Clean - Dust-Free Operations

Integrated filtration systems remove fine particles from the air, protecting both equipment and employee health.

Tailored solutions for every industry

Lundberg Tech delivers waste‑handling systems precisely adapted to each company’s sector, production type, and material streams. This means industries such as label converting, printing, packaging, film extrusion, laminating, coating, and even medical and food production can get solutions that meet their specific requirements for capacity, hygiene, and operational reliability.

The design process always begins with a thorough analysis of the production flow:

Waste type and volume — paper, foil, labels, liners, plastic film, and more.

Collection points — from single machines to centralised systems spanning entire production halls.

Integration with existing equipment and automated processes.

The result is often systems that run with high uptime, minimal operator intervention, and long service life. From compact stand‑alone units placed directly at the production line to large central systems with piping, separators, and balers — every solution is engineered for efficiency and scalability.

Sustainability and circular economy integration

Beyond optimising operations, Lundberg Tech’s systems help companies achieve their environmental and climate goals. By capturing, cutting, and conveying waste in a controlled process, they ensure a consistent fraction that can be sent directly for recycling. This leads to:

Reduced landfill use and less loss of valuable raw materials.

Lower CO₂ emissions through fewer waste transports and better logistics efficiency.

Compliance with environmental standards such as ISO 14001 or the EU Green Deal targets.

Many customers integrate these solutions into their CSR strategies, and some combine them with energy recovery, where production waste becomes fuel for biomass plants. This not only creates economic benefits but also builds a strong, measurable environmental profile for reporting to customers and authorities.

Get in touch

Get in Touch

To learn more about Lundberg Tech’s waste‑handling systems and how they can optimise your production, reduce costs, and support your sustainability goals, please contact our team today. We’re ready to provide detailed information, technical guidance, and customised solutions designed to meet your exact operational needs.